Waterjets

This technology involves a cold cutting process that uses pure supersonic water, or water and abrasive, to erode material. An ultrahigh-pressure pump generates a stream of water with extreme pressure that is converted into velocity via a tiny jewel orifice, creating a supersonic stream as small as a human hair to cut soft materials. Garnet can be added to this supersonic stream to greatly increase cutting power. Water and garnet can exit the cutting head at nearly four times the speed of sound, making the waterjet capable of cutting steel over one foot thick. Pure and abrasive waterjet technologies combined can cut virtually any material, any shape, at any thickness. Pure waterjet cuts soft materials like gasket, foam, plastic, paper, disposable diapers, insulation, cement board, automotive interiors, carpet, food. Abrasive waterjet can cut hard materials like metal, ceramic, stone, glass and composites.

Waterjet Cutting for Multiple Materials

For fabricators in search of new opportunities, and for customers who want shops that provide greater value, waterjet cutting is too important to overlook.

For fabricators in search of new opportunities, and for customers who want shops that provide greater value, waterjet cutting is too important to overlook.

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

No matter what your project calls for, there is an advanced cutting equipment solution to enhance and expand your metal fabrication capabilities.

With a sole focus on building abrasive waterjet machinery, the newest generation of OMAX brand core products is the culmination of nearly 30 years of work.

At FABTECH, the metal fabrication industry can tap into the power of this in-person event to discover new innovations and become inspired.

The latest version of ProNest from Hypertherm Associates features an optional module that offers enhanced integration with Tekla PowerFab Connector.

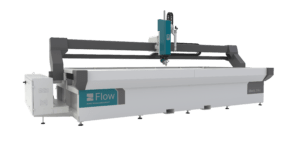

Cutting-edge waterjet solutions showcase Flow International Corp.’s continued commitment to advancing waterjet technology and expanding product lines to meet customers’ needs.

With the new HyproJET portfolio, CERATIZIT sets new standards for quality and durability.