Chucks

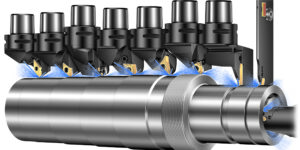

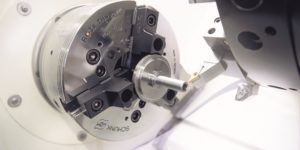

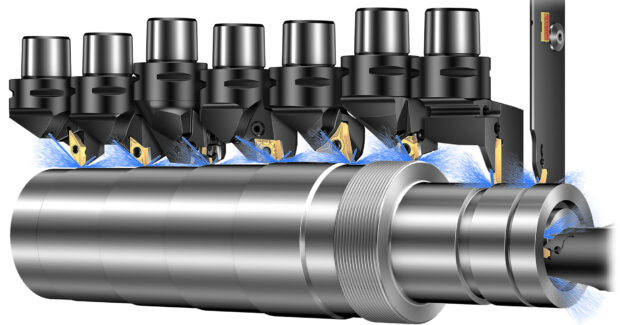

Chucks comprise a category of universal holding devices used in turning applications, capable of interior diameter or outer diameter (ID or OD) clamping. Chucks feature two to eight jaws, catered to fit the shape of the workpiece. Lathe chucks can be mounted vertically, horizontally, or inverted, and are operated either manually, electrically, hydraulically, or pneumatically. Along with standard jawed chucks, magnetic, electrostatic, and vacuum chucks also exist for custom applications.

Start Cutting Sooner with Quick and Hassle-Free Tools

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

Handle the toughest applications and cut down on the number of changes thanks to advances in tool life.

Getting the most out of your shop’s tool and workholding products leads to increases in uptime.

It’s time for machine tool builders and machining companies to shelf the long-standing ISO 1940-1 standard in favor of ISO 16084:2017. Not only is balancing tools rarely necessary, it can also be risky.

Just as the right workholding can improve your bottom line, inappropriate workholding can eat into profits. Make sure the chuck that came with your lathe isn’t keeping the machine from delivering the throughput and increased capacity it’s capable of.

HWR Workholding USA’s new products include the SOLIDGrip MAXX for large workpieces, and SOLIDBolt FLEXX for direct integration with pallets and tables of select machine tool builders, among others.

Sandvik Coromant’s Sustainability Analyzer is an upgraded version of the company’s existing Productivity Analyzer tool. The new tool provides detailed reporting on energy consumption per component, annual energy usage and annual CO2 emissions.

Manufactured from 6061 aluminum, 1018 steel, cast iron, and brass, Dillon Full Grip Jaws will not mark or mar the workpiece surface.