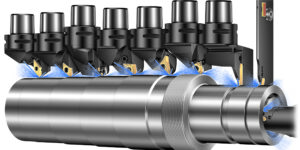

Drilling Tools

Drilling tools are end-cutting tools designed for producing holes in a workpiece. The shank of a drilling tool incorporates flutes, or grooves, that allow for the entrance of fluids, along with ejecting the cut ships from the workpiece. Drilling tools vary widely, to accommodate the properties of the workpiece along with the radius and depth of hole desired. Some subcategories of drilling tools include twist drills, straight flute drills, crankshaft drills, extension drills, step drills, oil hole drills, three- and four-fluted drills, and combination drill-and-countersink.

Solid Carbide Drills are Designed for Manufacturability

Solid carbide drills support innovative manufacturing, and due to their higher metal efficiencies contribute to and maximize a shop’s productivity levels.

Solid carbide drills support innovative manufacturing, and due to their higher metal efficiencies contribute to and maximize a shop’s productivity levels.

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

Sandvik’s PrimeTurning machining method supports competition among manufacturers, both for electric automobiles and other types of electric vehicles.

Manufacture with sharp cuts to produce precise shapes for your customers.

Exhibitors will showcase the latest in grinding technologies, sawing and cutoff machines, as well as a variety of finishing technologies.

CERATIZIT’s OptiLine Six-flute end mill features a premium substrate and advanced tool geometry.

The Walter USA solid-carbide orbital drill/thread mill, the TC685 supreme thread milling cutter, is for hard machining of the core hole and thread in one operation.

CERATIZIT’s additively manufactured MaxiMill – 211-DC indexable insert milling system with advanced coolant supply was developed for heat-resistant materials such as titanium and other super alloys.