Abrasives, Belts, Brushes, Grinding Wheels

This category includes systems and materials used to shape or finish a workpiece by using friction to wear away small particles of the piece. The abrasive process can be used to either smooth and polish the workpiece’s surface or to roughen it. Many abrasives incorporate a bonding system, where grains are held together with a fixative (grinding wheels), and coated systems, where abrasive grains are imbedded into a paper backing or a cloth. The groups of abrasive components include ceramic grain abrasives, silicon abrasives, aluminum oxides, and superabrasives (diamond and cubic boron nitride).

Abrasives Leap Forward: Extending Product Life Spans and Enhancing Performance

Inventive and next generation abrasives are having a transformative effect in shops that rely on the products for any number of applications.

Inventive and next generation abrasives are having a transformative effect in shops that rely on the products for any number of applications.

New engineered shaped ceramic grain stays sharp and keeps cutting with no significant increase in pressure throughout the life of the disc.

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

Even though flap discs are disposable, there are steps that can be taken to lengthen their usability. The result is less downtime, more work and greater savings.

Collect data from all aspects of your abrasives operation to provide a full picture and uncover the solutions needed to deliver time and cost savings.

WALTER Surface Technologies goes beyond the grain with exclusive new technologies to enhance product life.

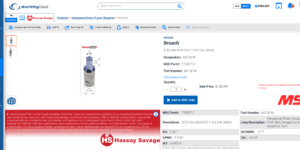

The new Walter WIS30 ceramic grade is proven to be efficient and reliable. Suitable turning and milling applications include roughing, semi-finishing and finishing, as well as interrupted cuts.

Suhner USA, Inc.’s ROTOmax 2.2 offers applications in cutting machining, grinding, rust removal, brushing or polishing.