Punches and Dies

Punches are simple tools that are forced by a punch press through a workpiece, commonly sheet metal, to create quick, precise holes by shearing. Punches are typically made of carbides or tool steel. Most presses are operated mechanically, but simple hand punches also are used. A punch frequently passes through the material and into a die. A die holds the workpiece, and determines the shape produced on it by the punch. Dies are usually customized to the particular item being produced.

FABTECH 2023-“Driving Manufacturing Forward”

FABTECH Heads to Chicago’s McCormick Place from September 11-14!

FABTECH Heads to Chicago’s McCormick Place from September 11-14!

To reduce wear and tool breakage when forming or blanking AHSS material, here are some tips on revisiting the type of tool steel used, the design of the tool itself, and whether or not adding a coating or surface finish will improve performance and provide longer tool life.

To prevent lower quality parts and frequent tool replacement, keep your punch press tooling sharp and well maintained to achieve the greatest number of hits possible for the best possible return on your investment.

Proper die clearance allows for upper and lower fracture lines to connect. The typical stamping industry rule of thumb is to use 10 percent material thickness as clearance between the punch and die button, but this guideline does not take into account variable material types. What is the optimal die clearance?

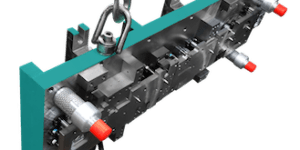

Does limited punching capacity and outsourcing lead times cause production delays in your shop? Here is a simple, affordable and effective system that can expand the capabilities of your press brakes, help streamline operations and eliminate the need for outsourcing or purchasing new equipment.

GibbsCAM announces the release of GibbsCAM 2024, which continues to boost end-user productivity for programming advanced machining centers, underpinning the GibbsCAM promise of Powerfully Simple, Simply Powerful.

Since the One-Hit-Hinge does not have to be formed straight up and curled down (3-hi style), the hinge diameter can be larger and will not interfere with the machine gap.

Throw out your rubber bands and twist-wire! Superior Die Set’s Cage Saver retracts ball bearing retainer cages during die-handling and maintenance and protects the assembly from water and detergent during pressure washing.