Software

FABTECH 2023 – METALFORM, Finishing, Tube & Pipe

Hall D: METALFORM, Finishing, Tube & Pipe of FABTECH 2023, North America’s largest metal forming, fabricating, welding and finishing event.

Hall D: METALFORM, Finishing, Tube & Pipe of FABTECH 2023, North America’s largest metal forming, fabricating, welding and finishing event.

Solid carbide drills support innovative manufacturing, and due to their higher metal efficiencies contribute to and maximize a shop’s productivity levels.

Take your production to the next level with products that are easy to use, adjust and change.

Leverage machine learning to make better decisions in real time.

The Smart Factory uses cyber-physical automation for tool management at every stage: from purchasing to programming to operation; from selecting, ordering and maintaining the proper tools for particular jobs to precise recommendations for cutting data to generating CNC programs for specific applications.

Sandvik Coromant announces CoroCut® QD for Y-axis parting. Optimized to enable improved surface quality, reduced vibration and higher blade stiffness.

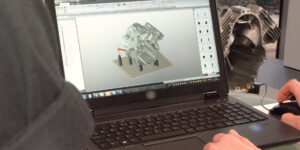

Renishaw’s FixtureBuilder allows quick creation and documentation of advanced CAD-based metrology fixturing setups for repeatable and productive part inspection. Full CAD compatibility, custom libraries, and a “Build It” function that automates set ups and simplifies purchasing of components.

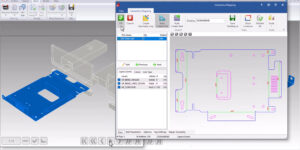

SigmaNEST, is pleased to announce version 24 of the software suite. The new release gives fabricators the tools to reach higher productivity throughout the shop, while being easy and intuitive to use. SigmaNEST 24 suite helps users in three ways: Deeper software integration, a more effective UI, and CAD/CAM enhancements that drive predictably high-quality output at the machine.