Vises and Vise Jaws

Vises consist of two parallel jaws that clamp together to securely hold a workpiece. In most vises, one jaw is movable by lever or screw, while the other jaw is fixed in place. Vises are made of various materials and can include temporary jaws of sheet copper or leather to cover the permanent surfaces when soft workpieces are being machined. Some vises are able to swivel or pivot in relation to the base, so that the workpiece can be held in a variety of positions. Vises are manufactured in numerous sizes for a variety of uses, from portable hand vises bolted to a workbench, to pipe vises used by plumbers, to angle and rotary vises.

Formidable, Powerful Workholders Provide Optimal Clamping Force

Secure your workpieces with robust clamping forces, innovative designs and quicker setups.

Secure your workpieces with robust clamping forces, innovative designs and quicker setups.

Handle the toughest applications and cut down on the number of changes thanks to advances in tool life.

With the right tools and CAM software, toolmakers and mold makers can keep production capacity flexible and will be able to ramp it up by up to 85% as they restart after the coronavirus outbreak. Hoffmann Group USA’s director of milling explains.

Even though it has been around forever, does the vise have limitations for shops in a competitive marketplace? Do you need to reinvent the wheel to reduce some of its limitations? To evaluate the vise’s viability in today’s manufacturing operations, we need to uncover the most efficient way to apply it.

Examine the design of these machine tool vise jaws to understand how they enable aggressive 5-axis machining of high-value medical and aerospace parts in a single setup by clamping on as little as 2 mm of surface.

The patented Multi-Jaw Rotating Bench Vise from Palmgren is one of the most versatile vises on the market. The jaws of the exceptional Bench Vise swivel 360° on the base and can lock in any position. Its unique shaped body…

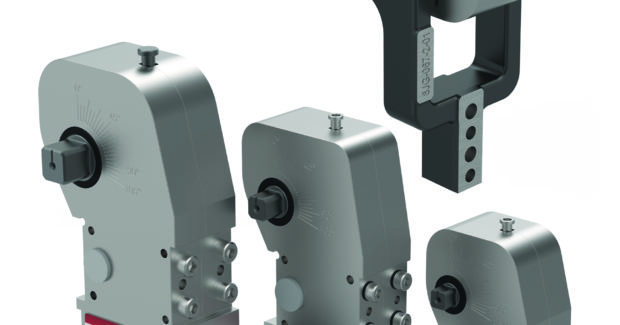

HWR Workholding USA’s new products include the SOLIDGrip MAXX for large workpieces, and SOLIDBolt FLEXX for direct integration with pallets and tables of select machine tool builders, among others.

Sandvik Coromant’s Sustainability Analyzer is an upgraded version of the company’s existing Productivity Analyzer tool. The new tool provides detailed reporting on energy consumption per component, annual energy usage and annual CO2 emissions.