Filler Metals/Electrodes

Filler metals are alloys or pure metals that are heated to liquefy, melt and flow into the space between two close fitting parts, creating a brazed or soldered joint that meets specific requirements for strength and corrosion resistance. Welding electrodes are metal wires with baked-on chemical coatings. The rod sustains the welding arc and is the filler metal used for the joint being welded. The coating protects the metal from damage, stabilizes the arc, and improves the weld. The type of base metal being welded, the welding process and machine, and other conditions determine the type of welding electrode used.

Busted: 5 Myths About Metal-Cored Welding Wire

Metal-cored wire isn’t new, but there are often misconceptions about applications, cost, performance, strength, and workability compared to solid wire. Read on to learn how you might be missing opportunities to increase welding operation productivity for less cost.

Metal-cored wire isn’t new, but there are often misconceptions about applications, cost, performance, strength, and workability compared to solid wire. Read on to learn how you might be missing opportunities to increase welding operation productivity for less cost.

To improve welding productivity, quality and cost savings, select the type and weight of welding wire packaging that balances out the time and cost for changing over the package with the equipment being used and the rate at which the product is consumed. Here’s how it works.

Selecting the proper filler metals for a given welding application can be difficult and confusing. To better understand what impacts filler metal strength, consider these four common misconceptions, along with guidelines to rectify them.

Resisting change is human nature, but change doesn’t have to be difficult. Qualifying different MIG, pulsed MIG or RMD welding procedures and processes for your jobsite is easier than you think – and a smart investment that can significantly improve productivity and save you money.

Filler metal used in welding pressure vessels must provide the appropriate impact toughness to meet strict design temperature requirements. Let’s examine the challenges of finding filler metal combinations, along with obtaining necessary documentation or testing to support welding procedures that can meet the mechanical properties of A516 Gr 70 plate.

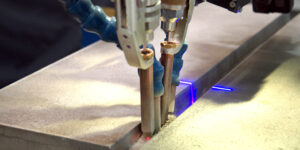

The semi-narrow gap welding SAW process uses fewer consumables resulting in a strong bond in less time and with fewer costs.

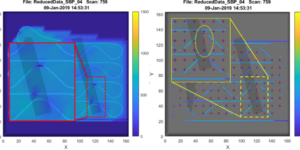

Fabrisonic’s new SmartPlate™ includes embedded sensors made to a customer’s specifications. Extract data from the sensors for real-time or post-processing analysis.

ESAB Welding & Cutting Products has introduced Marathon Pac™ Ultra, a new 1,100-lb. bulk welding wire drum, that features a robust outer box and reinforced corners for stabilizing the inner drum to prevent wire movement during shipping. Marathon Pac Ultra retains ESAB’s trademarked octagonal inner drum, known since 1989 as the industry benchmark, as well as ESAB’s reverse coiling technology to ensure that the wire comes out straight for greater process stability, less spatter and better targeting, positioning the wire at the center of the weld joint.