Inverter Welders

An inverter-based power source electronically increases and controls the frequency of the primary power supply before it enters the transformer, using electronic switches to turn power on and off extremely quickly and convert the power supply into a lower usable output voltage with improved electrical characteristics for welding, such as faster response time and more control for pulse welding.

New SWR-TIPTIG to Supercharge Productivity and Change How Industries Weld

The new Spool Welding Robot-TIPTIG mechanized TIG welding system from Novarc Technologies allows operators to make the highest quality welds with speeds two-to-three times faster than manual TIG welding

The new Spool Welding Robot-TIPTIG mechanized TIG welding system from Novarc Technologies allows operators to make the highest quality welds with speeds two-to-three times faster than manual TIG welding

When you’re on the job, there’s bound to be a mishap from time to time. What matters most in those moments is the solution you choose to fix it.

Regardless of your skill level, using subpar equipment will put your work at risk or make it harder to optimize output.

The road to AI for welding processes includes high-resolution data acquisition, high-speed data transfer and storage through networked products, and AI/ML algorithms.

Adopt technologies that handle market pressures and empower workers to ensure your long-term success.

AMADA WELD TECH highlights its AC inverter welding power supplies with its MIB-300A and MIB-600A AC.

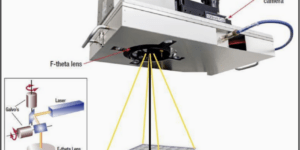

Quick and accurate point-to-point positioning can shave seconds off cycle times.

TRUMPF’s new arc-welding robot that programs its own weld path is now available in North America. The smart sensor enables the robot to determine weld spots automatically, and the technology helps tackle the shortage of skilled workers.